This website stores cookies on your computer. These cookies are used to collect information about how you interact with our website and allow us to remember you. We use this information in order to improve and customize your browsing experience and for analytics and metrics about our visitors both on this website and other media. To find out more about the cookies we use,

see our Privacy Policy.

Open House • Learn how you can grow your career with us! • May 15 • 3:00–6:00 p.m. • Merrimack, NH

Improve Operational Efficiency

Cisco Industrial Automation Networking Solution

For over a decade, manufacturers seeking to drive operational improvements have used Cisco’s Industrial Automation Networking solution to drive convergence and digitization. Industry 4.0 and industrial Internet of Things (IIoT) initiatives are driving improvements in manufacturers’ production processes and supply chains and enhancing product value. These initiatives require visibility and access to the data of the industrial automation and control systems (IACS) in production environments.

Moving Digital Manufacturing Forward

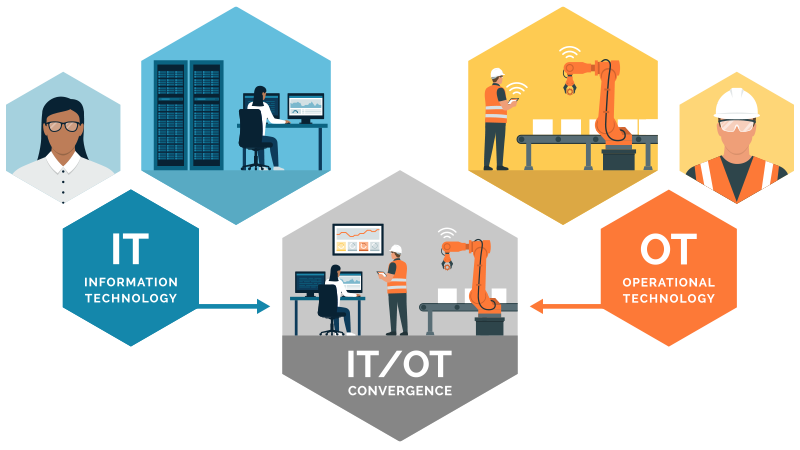

Historically, the information technology (IT) and operational technology (OT) departments within industrial manufacturing functioned independently. Operations kept the plant running smoothly, and IT managed business applications from the front office. The two teams occasionally collaborated on successful projects, such as implementing printers on the factory floor or servicing industrial PCs. Unfortunately, those opportunities were rare. Too often, it was a problem, not an opportunity, that brought IT and operations together. Whether it was a security incident, a system failure, or unplanned downtime, those encounters did little to breed trust and collaboration between the two teams. But the world of manufacturing is changing. To keep up, IT/OT relationships must change with it.All-in-One Solution

Asset Vision

Cisco Industrial Asset Vision has everything you need to monitor the health of your assets and facilities—integrated, secure, and ready to get going, including:- Cisco industrial sensors to provide telemetry and tracking information

- Cisco wireless gateway for LoRaWAN

- Secure, reliable, and long-range connectivity for outdoor and indoor industrial environments

- Manufacturing IoT with trusted Cisco Technology, so you do have to rely on unknown brands or 3rd party vendors

The Power of Cisco DNA in Industrial Automation Networks

Securely Connect and Digitize Industrial Environments

Industrial automation systems have fully adopted standard networking technologies and rely on them for the bulk of their communications. These networks must have the scale, flexibility, performance, and resiliency for these critical systems. This connectivity is the foundation for the industrial IoT and Industry 4.0 evolution—connecting sensors, actuators, and control systems to the machine-learning, digitization innovations in the cloud. IT/OT convergence in networking and security technology is not just established, but critical to a wave of optimizations and improvements in the ecosystem.Cisco DNA Center improves industrial operations by:

- Increasing overall equipment effectiveness and uptime

- Lowering operational costs

- Simplifying network management for IT and OT

- Enhancing security

Batch Add Products by Item #

16